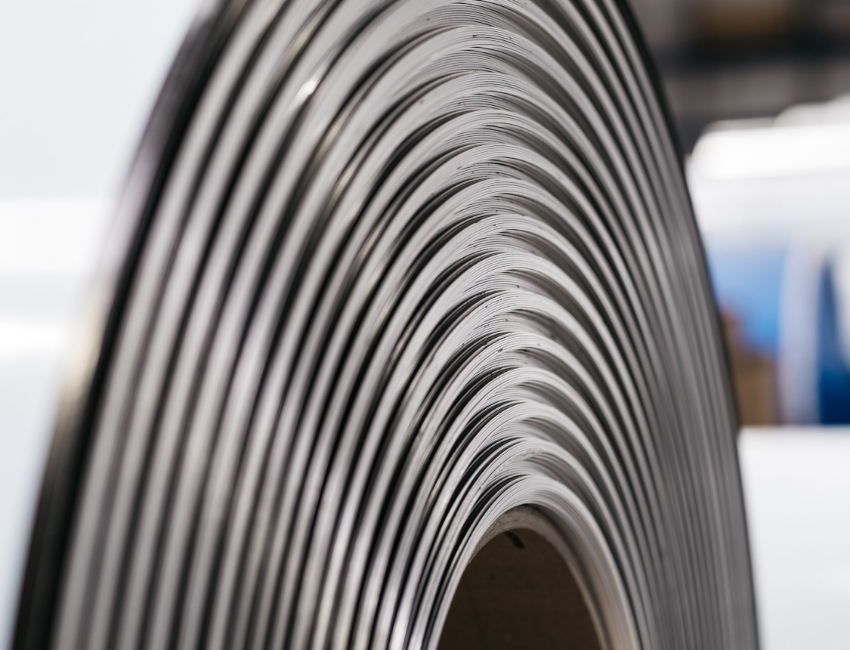

All the finishes you desire on aluminium coils.

La produzione interna delle polveri per verniciatura integra le nostre tecnologie per garantire la medesima qualità della verniciatura a polvere su profili e lamiere, ora estesa anche ai coil. Questo ci permette di offrire un'ampia gamma di effetti e colori, adatti a ogni applicazione, come automotive, architettura e industria.